Polyurethane Bushings

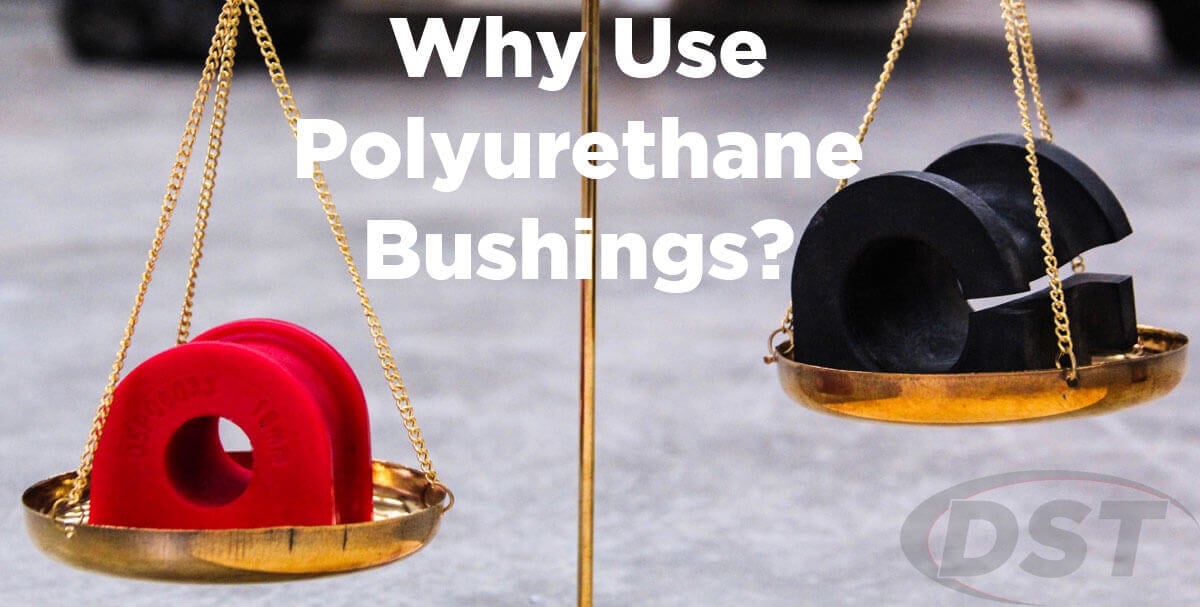

Polyurethane Bushings are an aftermarket alternative for replacing or upgrading the suspension bushings in a vehicle. There are a few reasons you might consider installing poly bushings but most boil down to finding a better balance between performance, durability, and comfort.

There are a lot of differences between a NASCAR stock car and a stock Honda Civic and one of those is the type of suspension in each. For racing, comfort is not really a consideration if a quarter second can be shaved off of a lap time, so the suspension is connected with metal spherical joints to control body roll and maintain traction during a turn. The average daily driver will have rubber bushings in these same positions to absorb vibration and noise from the road and provide a smoother ride overall.

The type of suspension in a vehicle is going to be decided by the purpose of the vehicle, but some folks might enjoy taking a corner like they’re in a stock car even if it’s only on the way to work. If you find yourself in that limbo between commuter and corner carver then polyurethane bushings are a great compromise that will deliver performance without making a daily driver unbearable.

TL;DR – Polyurethane bushings improve several aspects of how your vehicle handles but is usually accompanied by an increase in noise and vibration.

Table of Contents

Traits of Polyurethane Bushings

Durometer

One of the benefits that poly bushings bring to the table is also the greatest drawback: Hardness. The Durometer or hardness of the OE rubber bushings on most vehicles is between 50 and 60A. Polyurethane bushings range from 75 to 95A depending on the manufacturer and position. This means poly will not deflect or bend as much as your original bushings which result in better alignment holding and stability for your suspension parts but also increase NVH (noise, vibration, harshness).

Mechanical Bonding

Some positions are different, but when using a through-bolt poly bushings are allowed to “float” and are not fixed in the housing like OE rubber. So instead of the bushing itself torquing and wearing itself down, poly bushings allow more rotation instead of resisting internally, which provides a flexier suspension and consistent alignment of control arms or leaf springs.

Maintenance

There is some maintenance required since polyurethane bushings work best when lubricated to eliminate the chance of squeaking, be most effective, and extend their lifespan. The good news is that if lubricated during installation they should not need maintenance for 5 years or so. Some manufacturers even state that greasing at installation is the only time their bushings need lubrication.

Durability

Besides being very resistant to wear, polyurethane is also able to withstand motor chemicals, road salts, coastal climates, ozone, and other elements that can devour OE rubber. Not only do poly bushings have many performance advantages for cars but heavy-duty or extreme condition vehicles really benefit from the durability of polyurethane.

Are Polyurethane Bushings Worth It?

The answer to this question is based on many variables and each person will have their own opinion. Basically, If you’re looking for that sweet spot between comfort driven OE rubber bushings and the increased handling performance of unforgiving racing suspension then polyurethane bushings stand in that gap. We’ll take a look at a few of the biggest questions that should give you an idea of whether poly bushings are right for you.

How Do You Want Your Vehicle To Handle?

Poly bushings are noticeably harder than the stock OE rubber on your vehicle. This makes them a much better option for holding alignment of suspension parts like your control arms, leaf springs, or even isolating your differential. This translates to less body roll and more traction when turning. Solid metal options give you even more stability, BUT they are also exponentially rougher in terms of vibration and noise transfer.

How Do You Drive?

While the majority of us can’t afford the latest model speed demon it doesn’t stop us from driving like it. Sending more power to the wheels is fun but being able to control that power becomes more important the more fun we have. Poly bushings add stiffness to the suspension that allows you to take corners without throwing off the camber angle of your tires, which means they’ll stay flat against the pavement.

Desired Level of Comfort?

Poly bushings will transfer more vibration and noise in almost every case and for some this will be more noticeable than others. If your commute is comprised of well-maintained highways or the interstate then a more solid suspension should not bother you too much, but rougher roads will be felt a little more than with softer suspension bushings. This probably won’t be a concern for folks with off-road vehicles since a bumpy ride is part of the territory. Likewise with track cars since you’re on a smoother surface and performance outweighs comfort.

How Long Are You Keeping Your Vehicle?

Whether you’re restoring a classic that was buried under a pile of junk in a barn, or having the third set of body mounts installed on your work truck, then you know that there is a definite life (death?) expectancy for OE suspension bushings. Polyurethane is very resistant to wear, motor chemicals, road salts, and other elements that can harm the bushings on your vehicle. Many polyurethane bushing sets come backed with a lifetime warranty, so if you’re looking toward the future poly is a good bet.

When Should You Use Polyurethane Bushings?

Some suspension bushing positions are a trade-off when using polyurethane while others are just a straight upgrade. In almost every case you’ll be giving up some NVH reduction for performance benefits, but each will affect different aspects of your vehicle’s suspension. The following list will give you an idea of which poly bushings do what, plus the benefits and drawbacks.

First of all, polyurethane bushings are not strictly better than rubber. They will upgrade your handling, suspension stability, and have increased lifespan so they will be more favorable to folks that enjoy track car handling from their car or for heavy-duty and off-road vehicles, but they won’t do you any favors when it comes to vibration absorption. This should be considered when comparing poly and rubber bushings.

All Around Upgrade:

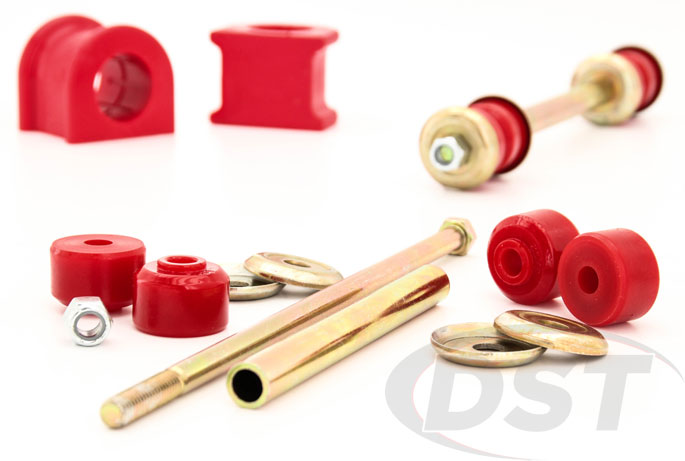

Sway Bar Bushings, Endlinks, and Dust Boots

The sway bars on your vehicle keep the driver and passenger side wheels connected and controls the amount that the body “rolls” or shifts to the outside when you turn. These bars are held in place by bushings and the stiffness and deflection of those bushings affect how well the sway bar does its job. Polyurethane deflects much less than OE bushings and provides such a grip on the sway bar that it actually makes a smaller sway bar perform like a larger, more expensive one. The best part is that since the sway bar is only connected to the frame by the bushings, stiffer poly will transfer almost no extra NVH to the driver. This part is a win-win.

Dust boots cover the open area of articulating parts like ball joints and tie rod ends, to keep debris from entering those joints and causing premature wear. Since poly is so much more durable than the OE this is another position where you get all benefit and no drawback.

More Power:

Differential Bushings, Motor and Transmission Mounts

Motor and transmission mounts require 1) strength to keep those parts aligned and 2) cushion to soften the full force of your engine’s vibrations. If it sounds like those two attributes don’t go together you’re right and we have examples of each extreme with rubber or solid metal. If we go back to our race car vs daily commuter analogy: OE rubber mounts = most comfort, least stability | Solid metal mounts = most stability, least comfort.

Again, polyurethane slips in-between these two options and provides a performance-minded alternative that won’t soak up power the engine is sending to the wheels like rubber and won’t shake loose your fillings on the way to work like solid metal mounts. Differential bushings hold the differential which channels power from the engine to the wheels of the vehicle and follows the same logic as the motor mounts: firmer gets you more power, softer smooths out the ride but also increases the chance of wheel hop.

Better Cornering:

Control Arm Bushings, Leaf Spring Bushings

Control arms and leaf springs are suspension parts that connect the wheel assembly or axle to the frame of your vehicle and at the end of those connection points are bushings. Without bushings your ride would be very harsh, but if they’re too soft then the camber angle of your wheels can be affected or the thrust angle of a vehicle with a rear axle. This can lead to steering wander and premature tire wear.

Poly control arm bushings give you much better tire alignment in a turn but will send more road noise and vibration to the driver. Same with the leaf spring bushings.

Body to Frame:

Body Mount Bushings, Subframe Bushings

Body mount bushings are located at the connection points between the body and the frame of your vehicle and maintain alignment while cushioning your ride. The subframe bushings do the same for separated sections of the frame (subframe) that hold the engine or rear differential and suspension.

Firmer body mounts will maintain ride height longer and keep the body from sagging like OE mounts can once they age or are crushed by excessive stress like constant heavy payloads. Poly subframe bushings keep the subframes aligned with the frame, which is important for drivetrain alignment and can correct issues with throttle response and reduce the chance of wheel-hop.

Conclusion

In the end it all depends on what you want and how much you value suspension performance. Most vehicles are designed with comfort as the highest priority when it comes to suspension so there is some room for improvement in the performance department.

If you want to make your daily driver handle corners like it’s on rails then polyurethane bushings can give you that feeling, but you will also feel more of the road. If you put your work truck or SUV through a lot of heavy loads or rough trails poly bushings are a more durable and long lasting aftermarket alternative. Throttle response and alignment are other areas where polyurethane shines and while it does transfer more NVH than OE rubber the performance benefits will outweigh the cost for most folks, but it is a matter of personal preference.

If You’re Interested…

Here are some top notch poly bushing manufacturers. Durometers given are an approximation and will vary depending on the type of kit and position of bushing.

Randy Singleton

March 27, 2021 at 10:20 pmWhat bushings did a BMW325ci2004

Josh Daniels • Post Author •

March 29, 2021 at 8:19 amHey Randy,

You can see the parts we have available for that vehicle at Suspension.com, so you can check that out. If you don’t see what you’re looking for you can contact our customer support folks or if you have measurements for a specific part you can find bushings for several positions in the universal parts page, and our customer service folks can assist you with that as well.

Hope this helps.

Paul Bockman

February 7, 2022 at 9:38 amI bought a master bushing kit from you. Actually not from you but eBay made by your company. It may have been from you. But through e bay.

The bushings for the rear springs and shackles are not right.

I’m not blaming you just need correct ones. Some previous owner put a different rear axle on the truck.

It’s a 1974 W100 truck. The bushings are regular rubber encased in a steel sleeve. But I want red bushings that match the front and body bushings.

The inner sleeve is 2.75

Outer sleeve diameter is 1.25

Bolt diameter is .625

And inner diameter is.875.

Can you send me part number and so I can order 6 of them.

Your time is much appreciated.

Josh Daniels • Post Author •

February 15, 2022 at 9:13 amHey Paul,

We aren’t seeing a bushing that fits those exact dimensions but there are some that are close. It’s hard to be sure we’re talking about the same dimensions in a comment thread but here are two to look at:

9.9488

9.9485

It would be a good idea to call or chat with our customer service folks to double check and make sure you get the right parts.

Hope we can help you find something that will work.